Ez Wiring Harness Instruction Manual

Posted By admin On 03.09.19Jun 21, 2018 - CycleGard 400 Series Installation Sheet. Hydrostat Remote Mounting Kit Instructions Safgard EZ Plug Wire Harness Installation Manual.

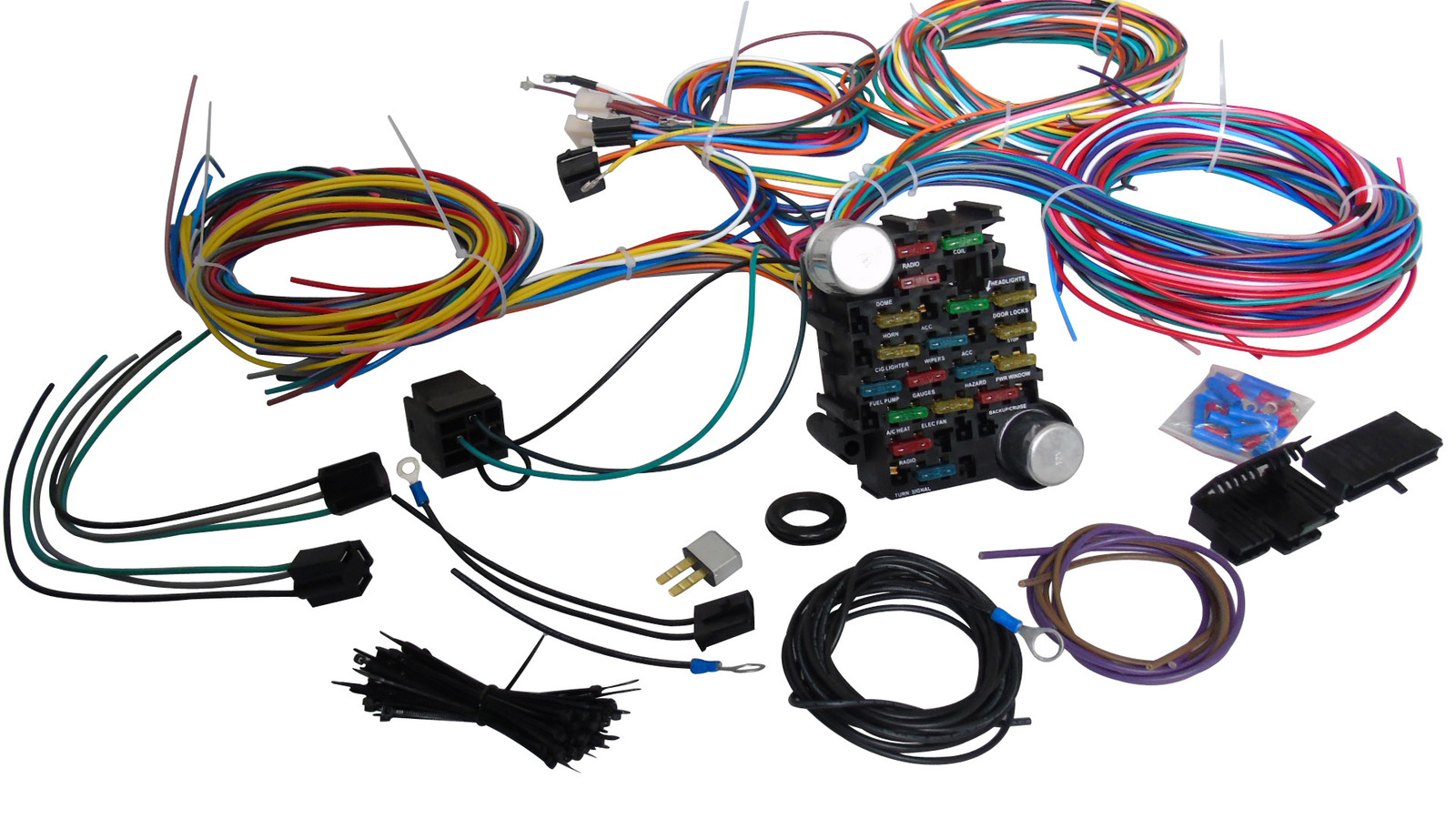

I'm trying to finish up the installation of the wiring harness (EZ Wiring 21 circuit) in my '55 Cameo. The harness installation was started by the previous owner but not finished. In hindsight I probably should have just gutted the wiring and started new. I've got the wiring from the firewall forward finished and the truck now turns over and runs (although the timing is way out but that's another story). With the ignition on, I have coil power (and solenoid power in the start position) but currently have no power at all at the fuse block. I noticed that the ignition accessory power had come loose from the connection on the column (the truck has a 1979 Camaro/Firebird tilt column in it).

Reconnecting it did not feed power back to the fuse block when the key is on. I'm assuming main power comes in through the 10 gauge wire from the battery terminal on the solenoid to the fuse block, feeds to the ignition, and then is fed back to the fuse panel to power the circuits when the ignition is on? The accessory power lead was just to the right and down from the last wire on the right in the photo.

Could anybody provide some advice as to what to look for? I don't understand why the fuse block is dead. The installation manual I'm sure the previous owner got with the harness likely would have been a huge help! Thanks in advance.

The EZ Wire instructions are available online. If it were me, I would copy the instructions, and start at step 1.

Ez Wiring Harness Instruction Manual

Ive used the EZ wire harness before. I wont say that the instructions were the worst Ive ever used, but they definitely were not the best. Seems odd to me that you can start the engine and dont have power to the fuse block. Since the PO did not complete the harness installation, he or she may have been in a little over their head, so I would be skeptical of any connections that have been made. Copy the intructions, step back, take a breath, disconnect the batterry, and start over. EZ wiring does not send complete wiring diagram with harness.

They give alt, ignition switch wiring for different makes, but that's about all. Now for your question. The 10 gauge red wire should hook directly to battery, normally at the post on the solenoid. GM uses red wires for hot all the time and pink wires for ignition hot. Also there should be another 10 gauge wire that goes to positive post on alt. Since you have a all black harness, you should get a wiring diagram for a GM car with your column ignition switch and use that to figure out if wires are hooked correctly.

My diagrams are at shop. I'm sure another Hamber has them on file. I'm trying to finish up the installation of the wiring harness (EZ Wiring 21 circuit) in my '55 Cameo. The harness installation was started by the previous owner but not finished. In hindsight I probably should have just gutted the wiring and started new. I've got the wiring from the firewall forward finished and the truck now turns over and runs (although the timing is way out but that's another story).

With the ignition on, I have coil power (and solenoid power in the start position) but currently have no power at all at the fuse block. I noticed that the ignition accessory power had come loose from the connection on the column (the truck has a 1979 Camaro/Firebird tilt column in it). Reconnecting it did not feed power back to the fuse block when the key is on. I'm assuming main power comes in through the 10 gauge wire from the battery terminal on the solenoid to the fuse block, feeds to the ignition, and then is fed back to the fuse panel to power the circuits when the ignition is on?

The accessory power lead was just to the right and down from the last wire on the right in the photo. Could anybody provide some advice as to what to look for?

I don't understand why the fuse block is dead. The installation manual I'm sure the previous owner got with the harness likely would have been a huge help! L oking at the picture of the switch, it looks like you are missing 1 wire, You should have 6 wires and I only see 5, there should be one wire on the bottom,far right side, that has the biggest connector on it, and it is the Ign. Feed to the fuse panel. All the rest are in the right places. Look to see if that wire is there, maybe I just cant see it in the picture.

If it's not there, look for it close by, maybe just hanging there??? Thanks in advance.

Installing An EZ Wiring Harness I don’t know about you but I’m perfectly happy fabricating chassis, welding and doing body and paintwork, and physically putting a car together, but I’ve always left the wiring in my projects to someone else. Of course, having a good friend who owned an auto-electrical company, and who was always happy to trade bodywork favors for wiring, meant I never really had to worry much, but he’s on the other side of the planet now and so when it came time to wire my ’46 I decided to bite the bullet and tackle the job myself. My cars are usually pretty basic with not much in the way of accessories– not even a radio–so I figured a simple wiring harness with the minimum of circuits would work best for someone who’d never wired a car before. After a little research, EZ Wiring’s 12-circuit harness looked perfect for my needs, so I called ’em up and ordered one. However, the project then somehow became relegated to the back burner for a couple of years, and it wasn’t until I decided to drive the truck to Bonneville last year that I actually dug out the still-boxed kit and took the plunge.

The installation was pretty straightforward and pain-free, if you disregard the couple of errors made by me and the need to fabricate a mount for the fuse box. Methodically following the instructions and breaking the job down into sections like engine harness, front of car, rear of car, and interior certainly made things easier, especially as I didn’t unravel one section’s wires until I’d completed the last. That way there weren’t a whole bunch of wires all over the place. With the exception of the turn signal switch, everything worked fine the first time. Somewhat pleased with myself, I’ll certainly tackle the wiring in the Project ’49 Chevy myself, and may even move on to doing my own upholstery next. EZ Q&A We asked Sean Schlobom of EZ Wiring to clear up some commonly asked questions regarding wiring, as well as to give us a couple of important dos and don’ts. Here’s what he had to say: R&C Bad grounds are probably high on the list of causes of wiring faults.

What can be done to ensure a good ground, and if I’m building a ‘glass car, what’s the best way to get a good ground throughout the vehicle? EZ You need a good clean connection for a good ground. Make sure the metal is not painted where you’re connecting the ground. In a ‘glass car, to ensure a good ground throughout the vehicle, use a ground bus (a terminal block wired directly to the chassis) at the front of the vehicle, one for the interior and another at the rear. All grounds can be fed into these busses, knowing they have a good connection to the frame.

R&C When are relays needed? EZ They’re required any time a higher amperage component runs continuously, such as Halogen headlights, electric fan, horn or fuel pumps. A relay allows a device to draw power right from the battery. EZ A fusible link protects the fuse panel, and protects a wire two gauges larger than itself.

For instance in an EZ Wiring kit, a 10-gauge wire is protected by a 14-gauge fusible link. In my opinion it’s better than a Maxi fuse as it’s hard to determine what size fuse to use, and fuses don’t react quickly enough. When a system is loaded to above capacity a fusible link will burn off and protect the fuse panel.

R&C How does length of wire affect gauge size, or is resistance negligible in the length of wire in a car? I know your kits come ready to fit so this isn’t relevant but how do you determine what gauge wire to use for specific amperages? EZ Today’s wire is better than that available in the past.

With cross link polyethylene wire such as used by most aftermarket harness manufacturers, we can use a smaller gauge wire than we did previously. I’d always recommend checking with the manufacturer of a component or device to determine what gauge wire to use, Resistance is pretty negligible in the lengths of wires used in the average car, but the longer the distance, the larger the gauge wire should be used. R&C How many circuits do I really need if I’m building a bare-bones traditional highboy? (no radio, electric fan, etc.) EZ A 12-circuit harness will be more than enough for a basic hot rod.

R&C Why do my lights seem to dim or get bright depending on the engine rpm? EZ If the lights are dim, I’d first check for a bad ground at the light, but fluctuating brightness is usually caused by an inefficient alternator. You may need the next size larger, as the charging system is working its hardest at engine idle speed.

The most common size alternator we find on hot rods that use a number of electrical systems like electric windows and fans is an 80-100amp version. R&C What’s the best way to trace a short? And if my battery goes flat after sitting for a day or two, how can I find out why? EZ A draw test works best in these instances. Remove the negative battery cable and clip the negative side of a test light to the negative battery cable, and the positive side of the light to the positive battery terminal.

If the light comes on you have a short somewhere. 95 percent of the time it is in the charging system. To determine this, disconnect the alternator and see if the test light goes out. If not then start pulling fuses one by one and conduct a draw test each time, until you find the circuit that has the short. R&C Would you recommend crimping or soldering connections? EZ It’s very much down to the installer’s preference. Cold solder is the same as a bad connection, but if you prefer soldering, go ahead.

Study Guide Biology Maktaba study guide: history - maktaba.' - 1 introduction. The purpose of this book is to provide relevant material for each subject in o-level. Study guide biology maktaba shamila.

If you want to crimp, ensure you use good quality crimping tools. R&C How do I determine the size of battery (measured in Cold Cranking Amps–indicated on the battery itself) I need for my application? EZ I’m always of the opinion that bigger is better.

The more compression your engine has, the more cold cranking amps it will require to start it. Check what your engine would need in a stock configuration, and use a battery of at least that size. R&C You must have a list of important “do’s” and “don’ts” especially the latter.

EZ Don’t clean up your harness installation as you go when wiring from scratch. Always check the operation before zip-tying or taping.