400 Isl Engine Manual

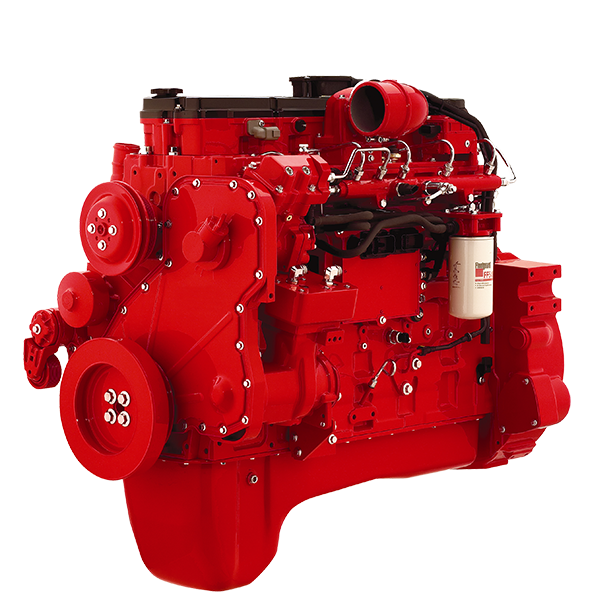

Posted By admin On 09.09.19To buy Cummins Parts and Service Manuals, Training Guides, or Tools go to our website at Owners Manual. ISL9 CM2350 L101. With horsepower ratings from 300 to 450 hp, Cummins engines will deliver the performance you expect and a. Cummins ISB and ISL engines provide better fuel economy than earlier models, as well as. Cummins ISL 8.9L, 400HP, 1,250 lb. CUMMINS DIESEL NH/NT 855 C.I.D. ENGINES SERVICE MANUAL. Includes CUMMINS 335 350 365 400 Engines and many more, see pictures for complete list.

Another possible cause could be an inaccurate gauge. In our coach, the analog gauges feed from a sensor installed by the motor home manufacturer. I have had problems with a number of these gauges. When I view the data directly from the engine sensors installed by Cummins, everything is fine. What gauge are you using for this data and what is the source of its input? If you don't have access to the engine data itself, you should be able to go to Cummins and get a read out of the engine codes which should let you know if the engine is actually overheating. Usually when things like the temperature are way out of spec, the engine computer will shut down the engine.

That's not limited to your Mandalay. It's been seen in Winnebagos and Allegro Buses as well. The common denominators are Freightliner chassis - 400 ISL - Side Radiator. I had a 2004 Allegro Bus that had similar issues. The root problem is that Freightliner uses a 1,050 sq in radiator in those years. The cooling package was not vertically stacked but instead was nested so that the charge air cooler and oil cooler all passed hot air over the radiator. That, coupled with the marginal size of the radiator made for some hot water temps in extreme situations.

Freightliner had a number of service campaigns that were performed to my '04 Bus but they all were dealing with baffling the airflow, reflective heat tape on the air intake hose, and chanbging the Dexron hydraulic fluid over to 15W-40 engine oil to keep the hydraulic radiator fan motor spinning better. But, none of those made an appreciable difference because they didn't deal with the root problem - which was an under-engineered cooling package. In fact, they had a another recall to replace the hydraulic oil coolers because they would burst under the pressure of the heavier motor oil that they were never designed to handle. I travel frequently out west and did plenty of long mountain grades. It was typical of the temp gauge going to 220 degrees and my MMDC's LCD display would flash the high temperature warning and sound the alarm. But, 220 degrees isn't the danger point.

It's a warning that you are getting there soon though. What I then did was manually downshift the Allison to keep the revs up. I didn't need to downshift to climb those grades because the 400 ISL has lots of torque and will lug up most anything. But, in order to keep the water pump spinning as fast as possible I had to downshift, which made me lose a few MPH, just to keep the water flowing from the engine to the radiator.

By doing that I was able to keep the temps from climbing. If I left it in automatic mode it would continue on to 235 degrees, at which time the engine would derate and lose power. It got to the point that I could recognize those grades ahead of time and do a manual shift ahead of time and I'd never quite get to the 220 degree alarm point. Just to put the radiator size in perspective - the Freightliner's in-line 1,050 sq in radiator compares to the Spartan vertically stacked radiator with 1,326 sq in. That's what I now have in my '07 Allegro Bus and it never ever overheats.

With the new 2007 spec (ULSD) engines, Freightliner has now gone to a 1,200 sq in radiator. Freightliner's cooling woes seemed to appear with the first emissions steps in 2003 so chassis in the 2003 to 2007 model years can have these issues. Another important factor is to keep the cooling system in top shape. Normally there's more tolerance but in this situation you do need to make sure that your cooling system is flushed regularly (I'd do it every 3 years) and your SCA levels are all proper.

Also makje sure that the radiator fins are immaculate. If there is any oily buildup on them, dirt will stick to the cooling fins and partially plug up your radiator's airflow. This is more common on rear radiator coaches but it's still something to look at on these side radiator coaches as well. Ideally you'd replace the coolant with an OAT coolant such as Final Charge or Fleetguard's ES Compleat OAT (formerlt Optimax). For details on that check out. I have a 2006 Cummins 400 ISL on a Spartan Chassis. The engine warning/alarm to shut down the engine comes on at 230 degrees for me which has happen several times.

However, three times in the last year the heat was so great it blew a hole in my heater hose, lost all my coolant, and left me stranded on the side of the road (Tennessee, New Mexico, and Texas) waiting for mobile diesel mechanics. Each time I replaced the entire heater hose with very high quality hose, but it still kept happening. My service center finally determined the problem.

It's a design flaw and a Cummins campaign item. Cummins changed the design in 2006 to where the hose coming right off the block is right next to the Turbo. They welded a piece of pipe coming off the engine block to re-route the hose and I have now had no more problems. Additionally, FYI, another Cummins campaign item is the fuel hose to the fuel rail on the pressure side. Another design flaw with numerous coomplaints and failures. Due to vibration the part will rupture right where it enter the rails and start spraying fuel (about 5 feet) out of the back of your coach.

It's a real fire hazard. Cummins has redesigned this part and will replace it at no charge if your engine is still under there 5 year warranty, after that, you have to pay for it. And yes, this just happened to me on my last trip and Coach-Net had me towed 98 miles to the nearest Cummins Service Center. I love Coach-Net. Hope this helps. I too have had what looks like overheating problems with a Cummins ISL 400 in a 2006 Newmar Dutch Star on a Spartan chassis. Temperatures on the Jellico Pass of I75 would run from 195 up to 235 on the dash gage.Then we blew a hose from the engine at the HydroHot system.

This hose was by Newmar. We replaced both the in and out hoses with quality hose and added a shut off valve back at the engine so if there was ever another problem we could isolate the HydroHot. I'm heading out again for the Jellico Pass 9/15, we'll see what trouble I find. Davis reports there is a bulletin on a radiator hose location fix and I will be following this as I know we've had no radiator service. BTW, Cummins tells me that 195 to 225 is normal - my car doesn't have this wide range! Fred Leport Union KY. I was sure those high temperatures must have been a gauge error.

I'm amazed to find them to be correct readings. Our 400 ISL runs between 173 and 183 except on the hottest days and steepest long grades. I've never seen it above 200 either on the analog or digital gauge. We have the side radiator which I measure to be about 1100 square inches. Our charge air cooler and transmission cooler are all nested. I never take the transmission out of its automatic mode and use the economy mode routinely. Our rig weights in at 36,000 pounds with a 6000 pound toad.

I wonder what the difference is in our set-up that makes such a difference in engine temperatures? We have a 2005/6 Mandalay with a Cummins 400 ISL and we have had trouble with overheating ( alarms going off at 225 + ) and I always blamed the problem on 1) towing a Jeep G.C., 2) climbing the hills and mountians between Texas, Minnesota, Washington state and Oregon, 3) the amount of weight we carried in the RV. It appears to me that the size of the side mounted raditator may be the main problem and I believe that either Freightliner or Mandalay should issue a recall and replacement because it was not designed with the right suze. We have a 2005/6 Mandalay with a Cummins 400 ISL and we have had trouble with overheating ( alarms going off at 225 + ) and I always blamed the problem on 1) towing a Jeep G.C., 2) climbing the hills and mountains between Texas, Minnesota, Washington state and Oregon, 3) the amount of weight we carried in the RV. It appears to me that the size of the side mounted radiator may be the main problem and I believe that either Freightliner or Mandalay should issue a recall and replacement because it was not designed with the right size. Have you verified that the hydraulic system (pump, controller, lines, filter/reservoir and fan) for your side radiator fan is working properly? If the fan is not going to the designed RPM under high-heat conditions, it will cause the same symptoms.

If you have checked all of the items suggested by members of the forum, and if you have pulled the radiator and had it checked for blockage and still found no problem. You can take a couple of steps to increase the cooling capacity of the package. One is to replace the heater valve with one that is a bypass valve (meaning that when the heater is off there is still flow through the heater coolant lines). If you can't find a valve that will work with your heating system then install a cable controlled bypass system ( 2 tees and a old time heater valve). This should solve most overheating problems. In more extreme cases, add a radiator behind the airconditioning condenser and feed it with the heater hoses, you may have to include a shutoff valve in order to get enough flow to the heater core to heat the coach.

Measure the condenser and fan width and check auto salvage yards to see what fits (try Ford Explorer). These are measures to explore after there is nothing left to repair and the unit is out of warranty. Had intermittent overheating on my 400 ISL, 03 CC Intrigue, side radiator.

After talking to a Cummins mechanic (not the service desk) in Albuquerque, I disconnected a 6 pin connector on the engine cooling fan controller. Disconnecting this plug causes the engine fan to run at highest speed, if the fan/controller is working properly (eliminates that as the problem). Took a while for the engine to heat up but I found the loaded temp ran around 185 degrees, the set point for the thermostat. Proved the termostat OK. Ran the Rockies and then central TX in 100 plus temps and never saw over 200 degrees on the Silverleaf (proves the cooling system has sufficient capacity). The 6 pin plug is coolant temp, air charge temp, power, ground. Replaced the coolant temp sensor and my problem went away.

Bottom line, disconnecting one plug COULD eliminate a lot of potential problems - easier to find the culprit. Had intermittent overheating on my 400 ISL, 03 CC Intrigue, side radiator. After talking to a Cummins mechanic (not the service desk) in Albuquerque, I disconnected a 6 pin connector on the engine cooling fan controller. Disconnecting this plug causes the engine fan to run at highest speed, if the fan/controller is working properly (eliminates that as the problem). Took a while for the engine to heat up but I found the loaded temp ran around 185 degrees, the set point for the thermostat. Proved the termostat OK. Ran the Rockies and then central TX in 100 plus temps and never saw over 200 degrees on the Silverleaf (proves the cooling system has sufficient capacity).

The 6 pin plug is coolant temp, air charge temp, power, ground. Replaced the coolant temp sensor and my problem went away. Bottom line, disconnecting one plug COULD eliminate a lot of potential problems - easier to find the culprit. While unplugging (or otherwise forcing the fan to high speed) is an excellent diagnostic tool (just as cwmarch dithermostatd), please do not consider it a long-term solution. You will be giving up way too many HP and MPG.

Counterpoint: I've read a lot about Freightliners with the ISL overheating, but that has not been a problem on my 2004 American Tradition (Freightliner/Liberty chassis with side radiator 370ISL). My temps run 186-197 just about all the time.

I did hit 202-207 a couple times pulling a long 6% grade in summer weather, but never had to bump the revs up or anything like that to keep it in an acceptable range. In another words, mine cools just fine. These temps are from my TripTek monitoring system, so they are right from the ECM data bus and not a dashboard gauge. I'm thinking the coach body design may have some effect on air flow through the side radiator, enough so that the relatively small FL radiator can be overtaxed in one coach but OK in another.

I have a 2007 Mandalay 40E 400 Cummins. I pull a Jeep.

It never ran over 200 degree. My unit was made in late 2006 did they change the radiator size in 2007 models? Also I can't get over 5.7 MPG I talk to a person that had a 2008 425 Cummins and claims he get 9-10 MPG Greg, Welcome to the FMCA Forum. I would agree 5.7 MPG is low. Questions: 1.

Is your speedometer/odometer accurate (vs GPS or Interstate mile makers)? Are you 'subtracting for fuel used by the generator? What is your GCW (Gross Combined Weight- loaded RV plus toad? Flat ground or hills/mountains? Regular or economy mode on Allison? How fast do you drive? As you can see, there are a LOT of variables when it comes to MPG.

And 9-10 MPG AVERAGE (not one tank) would be FANTASTIC- bordering on EXCEPTIONAL for your friend's/ANYONE'S late model heavy coach. Ansoft hfss 13 user guide. I have some questions in regards to Cwmarch's post.

Does the temp sensor just send info to gauges, or does it send info to a computer to help control engine temp? Where was the 6 pin connector located that you disconnected? I was not sure from your post if the overheat issue was gauge related or if the engine was running hot and the new temp sensor corrected it. My 06 Winne has been doing the same thing as others have described since day one.

Have gotten some of fixes mentioned but they have not solved the issue yet. My 2007 Itasca Horizon 40' has seen more Freightliner service centers then campgrounds since we purchased it. I have been told the overheating is cause by everything from bad fuel filters, clogged Radiator, bad sensor, changed, bad pump, changed, and on and on. I took it the last time to a Freightliner service center north of Denver Co. The mechanic did all the test and came back with the only sensible answer.

It is a great engineering goof up that Freightliner will not admit to. To over come the problem on hills and mountains you have to keep the RPMs at 2200 or above. I asked if there was a retrofit to put an electric fan drive with a temp control like most other manufactures have on the chassis and he told me not that he knows. So now we just watch and manual downshift, I don't know why they put cruse on the unit its a waste of money traveling the mountains. My 2007 Itasca Horizon 40' has seen more Freightliner service centers then campgrounds since we purchased it. I have been told the overheating is cause by everything from bad fuel filters, clogged Radiator, bad sensor, changed, bad pump, changed, and on and on. I took it the last time to a Freightliner service center north of Denver Co.

The mechanic did all the test and came back with the only sensible answer. It is a great engineering goof up that Freightliner will not admit to. To over come the problem on hills and mountains you have to keep the RPMs at 2200 or above.

I asked if there was a retrofit to put an electric fan drive with a temp control like most other manufactures have on the chassis and he told me not that he knows. So now we just watch and manual downshift, I don't know why they put cruse on the unit its a waste of money traveling the mountains I installed two spal 2200 cfm fans to the outside of the unit and had it run on a dyno twice. Once with the fans running and once with the fans off. With the fans running, we got 6 mins or 6 miles up the hill before reaching high temp alarm. I removed the fans after having the new pump and fan motor up grade, but the issue still exist and I'm thinking about reinstalling them. The electrical fans uses a thermostat sending unit which is plugged into the engine water jacket that operated independent of the factory system. I have some questions in regards to Cwmarch's post.

Does the temp sensor just send info to gauges, or does it send info to a computer to help control engine temp? Where was the 6 pin connector located that you disconnected? I was not sure from your post if the overheat issue was gauge related or if the engine was running hot and the new temp sensor corrected it. My 06 Winne has been doing the same thing as others have described since day one. Have gotten some of fixes mentioned but they have not solved the issue yet. Don't know everything the coolant sensor feeds.

Cummins Isl 400 Oil Filter

The sensor I replaced is in the upper radiator pipe/hose and has 2 leads that go to the fan controller(via the 6 pin). The 6 pin has short, approx 5' leads to the controller. My controller is mounted on the lower back of the fan box.

Follow the hydraulic lines from the fan motor - should lead to the controller. The engine was running hot, not just an indication problem. Evidentally the coolant sensor wasn't sending the correct signal to increase fan speed(intermittently). We too have experienced intermittent overheating with our Cummins 400 in a 2008 Winnebago Ellipse (rear radiator). On three occasions (June, Aug, & Sep) the engine coolant temperature quickly rose from normal (179-189) to 230.

Increasing engine speed made no difference, and in all three incidents we had to pull over and shut down the engine. Once we restarted the engine (the last time within 2-3 minutes of shutting it down) the coolant temperature immediately returned to the normal range, after which it operated normally. The latest incident, just two days ago, the ambient temperature was in the fifties and we were on a relatively level stretch of interstate traveling at 55 mph.

With the exception of these three incidents, the engine coolant temperature falls in the 179-189 range except for very hot days and/or significant grades (when it may go to 205 or so). We spoke with Freightliner Customer Service and the tech suggested a faulty fan clutch. Does this seem possible? Many thanks to all for your insights.

Another possible cause could be an inaccurate gauge. In our coach, the analog gauges feed from a sensor installed by the motor home manufacturer. I have had problems with a number of these gauges. When I view the data directly from the engine sensors installed by Cummins, everything is fine. What gauge are you using for this data and what is the source of its input?

If you don't have access to the engine data itself, you should be able to go to Cummins and get a read out of the engine codes which should let you know if the engine is actually overheating. Usually when things like the temperature are way out of spec, the engine computer will shut down the engine. That's not limited to your Mandalay. It's been seen in Winnebagos and Allegro Buses as well. The common denominators are Freightliner chassis - 400 ISL - Side Radiator.

I had a 2004 Allegro Bus that had similar issues. The root problem is that Freightliner uses a 1,050 sq in radiator in those years. The cooling package was not vertically stacked but instead was nested so that the charge air cooler and oil cooler all passed hot air over the radiator. That, coupled with the marginal size of the radiator made for some hot water temps in extreme situations. Freightliner had a number of service campaigns that were performed to my '04 Bus but they all were dealing with baffling the airflow, reflective heat tape on the air intake hose, and chanbging the Dexron hydraulic fluid over to 15W-40 engine oil to keep the hydraulic radiator fan motor spinning better.

But, none of those made an appreciable difference because they didn't deal with the root problem - which was an under-engineered cooling package. In fact, they had a another recall to replace the hydraulic oil coolers because they would burst under the pressure of the heavier motor oil that they were never designed to handle. I travel frequently out west and did plenty of long mountain grades. It was typical of the temp gauge going to 220 degrees and my MMDC's LCD display would flash the high temperature warning and sound the alarm. But, 220 degrees isn't the danger point. It's a warning that you are getting there soon though. What I then did was manually downshift the Allison to keep the revs up.

I didn't need to downshift to climb those grades because the 400 ISL has lots of torque and will lug up most anything. But, in order to keep the water pump spinning as fast as possible I had to downshift, which made me lose a few MPH, just to keep the water flowing from the engine to the radiator.

By doing that I was able to keep the temps from climbing. If I left it in automatic mode it would continue on to 235 degrees, at which time the engine would derate and lose power. It got to the point that I could recognize those grades ahead of time and do a manual shift ahead of time and I'd never quite get to the 220 degree alarm point.

Just to put the radiator size in perspective - the Freightliner's in-line 1,050 sq in radiator compares to the Spartan vertically stacked radiator with 1,326 sq in. That's what I now have in my '07 Allegro Bus and it never ever overheats. With the new 2007 spec (ULSD) engines, Freightliner has now gone to a 1,200 sq in radiator.

Freightliner's cooling woes seemed to appear with the first emissions steps in 2003 so chassis in the 2003 to 2007 model years can have these issues. Another important factor is to keep the cooling system in top shape. Normally there's more tolerance but in this situation you do need to make sure that your cooling system is flushed regularly (I'd do it every 3 years) and your SCA levels are all proper. Also makje sure that the radiator fins are immaculate. If there is any oily buildup on them, dirt will stick to the cooling fins and partially plug up your radiator's airflow. This is more common on rear radiator coaches but it's still something to look at on these side radiator coaches as well. Ideally you'd replace the coolant with an OAT coolant such as Final Charge or Fleetguard's ES Compleat OAT (formerlt Optimax).

For details on that check out. I have a 2006 Cummins 400 ISL on a Spartan Chassis. The engine warning/alarm to shut down the engine comes on at 230 degrees for me which has happen several times. However, three times in the last year the heat was so great it blew a hole in my heater hose, lost all my coolant, and left me stranded on the side of the road (Tennessee, New Mexico, and Texas) waiting for mobile diesel mechanics.

Each time I replaced the entire heater hose with very high quality hose, but it still kept happening. My service center finally determined the problem. It's a design flaw and a Cummins campaign item.

Cummins changed the design in 2006 to where the hose coming right off the block is right next to the Turbo. They welded a piece of pipe coming off the engine block to re-route the hose and I have now had no more problems. Additionally, FYI, another Cummins campaign item is the fuel hose to the fuel rail on the pressure side. Another design flaw with numerous coomplaints and failures. Due to vibration the part will rupture right where it enter the rails and start spraying fuel (about 5 feet) out of the back of your coach. It's a real fire hazard. Cummins has redesigned this part and will replace it at no charge if your engine is still under there 5 year warranty, after that, you have to pay for it.

And yes, this just happened to me on my last trip and Coach-Net had me towed 98 miles to the nearest Cummins Service Center. I love Coach-Net. Hope this helps. I too have had what looks like overheating problems with a Cummins ISL 400 in a 2006 Newmar Dutch Star on a Spartan chassis. Temperatures on the Jellico Pass of I75 would run from 195 up to 235 on the dash gage.Then we blew a hose from the engine at the HydroHot system. This hose was by Newmar.

We replaced both the in and out hoses with quality hose and added a shut off valve back at the engine so if there was ever another problem we could isolate the HydroHot. I'm heading out again for the Jellico Pass 9/15, we'll see what trouble I find. Davis reports there is a bulletin on a radiator hose location fix and I will be following this as I know we've had no radiator service. BTW, Cummins tells me that 195 to 225 is normal - my car doesn't have this wide range! Fred Leport Union KY.

I was sure those high temperatures must have been a gauge error. I'm amazed to find them to be correct readings. Our 400 ISL runs between 173 and 183 except on the hottest days and steepest long grades. I've never seen it above 200 either on the analog or digital gauge. We have the side radiator which I measure to be about 1100 square inches. Our charge air cooler and transmission cooler are all nested. I never take the transmission out of its automatic mode and use the economy mode routinely.

Our rig weights in at 36,000 pounds with a 6000 pound toad. I wonder what the difference is in our set-up that makes such a difference in engine temperatures?

We have a 2005/6 Mandalay with a Cummins 400 ISL and we have had trouble with overheating ( alarms going off at 225 + ) and I always blamed the problem on 1) towing a Jeep G.C., 2) climbing the hills and mountians between Texas, Minnesota, Washington state and Oregon, 3) the amount of weight we carried in the RV. It appears to me that the size of the side mounted raditator may be the main problem and I believe that either Freightliner or Mandalay should issue a recall and replacement because it was not designed with the right suze.

We have a 2005/6 Mandalay with a Cummins 400 ISL and we have had trouble with overheating ( alarms going off at 225 + ) and I always blamed the problem on 1) towing a Jeep G.C., 2) climbing the hills and mountains between Texas, Minnesota, Washington state and Oregon, 3) the amount of weight we carried in the RV. It appears to me that the size of the side mounted radiator may be the main problem and I believe that either Freightliner or Mandalay should issue a recall and replacement because it was not designed with the right size. Have you verified that the hydraulic system (pump, controller, lines, filter/reservoir and fan) for your side radiator fan is working properly? If the fan is not going to the designed RPM under high-heat conditions, it will cause the same symptoms. If you have checked all of the items suggested by members of the forum, and if you have pulled the radiator and had it checked for blockage and still found no problem. You can take a couple of steps to increase the cooling capacity of the package.

One is to replace the heater valve with one that is a bypass valve (meaning that when the heater is off there is still flow through the heater coolant lines). If you can't find a valve that will work with your heating system then install a cable controlled bypass system ( 2 tees and a old time heater valve). This should solve most overheating problems. In more extreme cases, add a radiator behind the airconditioning condenser and feed it with the heater hoses, you may have to include a shutoff valve in order to get enough flow to the heater core to heat the coach.

Measure the condenser and fan width and check auto salvage yards to see what fits (try Ford Explorer). These are measures to explore after there is nothing left to repair and the unit is out of warranty. Had intermittent overheating on my 400 ISL, 03 CC Intrigue, side radiator. After talking to a Cummins mechanic (not the service desk) in Albuquerque, I disconnected a 6 pin connector on the engine cooling fan controller. Disconnecting this plug causes the engine fan to run at highest speed, if the fan/controller is working properly (eliminates that as the problem).

Took a while for the engine to heat up but I found the loaded temp ran around 185 degrees, the set point for the thermostat. Proved the termostat OK. Ran the Rockies and then central TX in 100 plus temps and never saw over 200 degrees on the Silverleaf (proves the cooling system has sufficient capacity). The 6 pin plug is coolant temp, air charge temp, power, ground.

Replaced the coolant temp sensor and my problem went away. Bottom line, disconnecting one plug COULD eliminate a lot of potential problems - easier to find the culprit. Had intermittent overheating on my 400 ISL, 03 CC Intrigue, side radiator. After talking to a Cummins mechanic (not the service desk) in Albuquerque, I disconnected a 6 pin connector on the engine cooling fan controller.

Disconnecting this plug causes the engine fan to run at highest speed, if the fan/controller is working properly (eliminates that as the problem). Took a while for the engine to heat up but I found the loaded temp ran around 185 degrees, the set point for the thermostat.

Proved the termostat OK. Ran the Rockies and then central TX in 100 plus temps and never saw over 200 degrees on the Silverleaf (proves the cooling system has sufficient capacity). The 6 pin plug is coolant temp, air charge temp, power, ground. Replaced the coolant temp sensor and my problem went away. Bottom line, disconnecting one plug COULD eliminate a lot of potential problems - easier to find the culprit. While unplugging (or otherwise forcing the fan to high speed) is an excellent diagnostic tool (just as cwmarch dithermostatd), please do not consider it a long-term solution.

You will be giving up way too many HP and MPG. Counterpoint: I've read a lot about Freightliners with the ISL overheating, but that has not been a problem on my 2004 American Tradition (Freightliner/Liberty chassis with side radiator 370ISL).

My temps run 186-197 just about all the time. I did hit 202-207 a couple times pulling a long 6% grade in summer weather, but never had to bump the revs up or anything like that to keep it in an acceptable range. In another words, mine cools just fine. These temps are from my TripTek monitoring system, so they are right from the ECM data bus and not a dashboard gauge. I'm thinking the coach body design may have some effect on air flow through the side radiator, enough so that the relatively small FL radiator can be overtaxed in one coach but OK in another. I have a 2007 Mandalay 40E 400 Cummins. I pull a Jeep.

It never ran over 200 degree. My unit was made in late 2006 did they change the radiator size in 2007 models? Also I can't get over 5.7 MPG I talk to a person that had a 2008 425 Cummins and claims he get 9-10 MPG Greg, Welcome to the FMCA Forum. I would agree 5.7 MPG is low.

Questions: 1. Is your speedometer/odometer accurate (vs GPS or Interstate mile makers)? Are you 'subtracting for fuel used by the generator? What is your GCW (Gross Combined Weight- loaded RV plus toad? Flat ground or hills/mountains?

Regular or economy mode on Allison? How fast do you drive? As you can see, there are a LOT of variables when it comes to MPG. And 9-10 MPG AVERAGE (not one tank) would be FANTASTIC- bordering on EXCEPTIONAL for your friend's/ANYONE'S late model heavy coach.

I have some questions in regards to Cwmarch's post. Does the temp sensor just send info to gauges, or does it send info to a computer to help control engine temp? Where was the 6 pin connector located that you disconnected? I was not sure from your post if the overheat issue was gauge related or if the engine was running hot and the new temp sensor corrected it. My 06 Winne has been doing the same thing as others have described since day one. Have gotten some of fixes mentioned but they have not solved the issue yet. My 2007 Itasca Horizon 40' has seen more Freightliner service centers then campgrounds since we purchased it.

I have been told the overheating is cause by everything from bad fuel filters, clogged Radiator, bad sensor, changed, bad pump, changed, and on and on. I took it the last time to a Freightliner service center north of Denver Co. The mechanic did all the test and came back with the only sensible answer. It is a great engineering goof up that Freightliner will not admit to. To over come the problem on hills and mountains you have to keep the RPMs at 2200 or above. I asked if there was a retrofit to put an electric fan drive with a temp control like most other manufactures have on the chassis and he told me not that he knows.

So now we just watch and manual downshift, I don't know why they put cruse on the unit its a waste of money traveling the mountains. My 2007 Itasca Horizon 40' has seen more Freightliner service centers then campgrounds since we purchased it. I have been told the overheating is cause by everything from bad fuel filters, clogged Radiator, bad sensor, changed, bad pump, changed, and on and on.

I took it the last time to a Freightliner service center north of Denver Co. The mechanic did all the test and came back with the only sensible answer. It is a great engineering goof up that Freightliner will not admit to. To over come the problem on hills and mountains you have to keep the RPMs at 2200 or above. I asked if there was a retrofit to put an electric fan drive with a temp control like most other manufactures have on the chassis and he told me not that he knows. So now we just watch and manual downshift, I don't know why they put cruse on the unit its a waste of money traveling the mountains I installed two spal 2200 cfm fans to the outside of the unit and had it run on a dyno twice.

Once with the fans running and once with the fans off. With the fans running, we got 6 mins or 6 miles up the hill before reaching high temp alarm.

I removed the fans after having the new pump and fan motor up grade, but the issue still exist and I'm thinking about reinstalling them. The electrical fans uses a thermostat sending unit which is plugged into the engine water jacket that operated independent of the factory system. I have some questions in regards to Cwmarch's post.

Does the temp sensor just send info to gauges, or does it send info to a computer to help control engine temp? Where was the 6 pin connector located that you disconnected? I was not sure from your post if the overheat issue was gauge related or if the engine was running hot and the new temp sensor corrected it. My 06 Winne has been doing the same thing as others have described since day one. Have gotten some of fixes mentioned but they have not solved the issue yet. Don't know everything the coolant sensor feeds.

The sensor I replaced is in the upper radiator pipe/hose and has 2 leads that go to the fan controller(via the 6 pin). The 6 pin has short, approx 5' leads to the controller. My controller is mounted on the lower back of the fan box. Follow the hydraulic lines from the fan motor - should lead to the controller.

The engine was running hot, not just an indication problem. Evidentally the coolant sensor wasn't sending the correct signal to increase fan speed(intermittently). We too have experienced intermittent overheating with our Cummins 400 in a 2008 Winnebago Ellipse (rear radiator). On three occasions (June, Aug, & Sep) the engine coolant temperature quickly rose from normal (179-189) to 230.

Increasing engine speed made no difference, and in all three incidents we had to pull over and shut down the engine. Once we restarted the engine (the last time within 2-3 minutes of shutting it down) the coolant temperature immediately returned to the normal range, after which it operated normally. The latest incident, just two days ago, the ambient temperature was in the fifties and we were on a relatively level stretch of interstate traveling at 55 mph. With the exception of these three incidents, the engine coolant temperature falls in the 179-189 range except for very hot days and/or significant grades (when it may go to 205 or so). We spoke with Freightliner Customer Service and the tech suggested a faulty fan clutch.

Does this seem possible? Many thanks to all for your insights.